Ensuring Safety and Longevity

Below-the-hook lifting equipment is crucial for safely and efficiently handling loads. Regular maintenance of these equipment not only ensures safety but also extends their lifespan. In this blog, we’ll cover key aspects of maintaining different below-the-hook equipment, including slings, clamps, hooks, and magnets.

1. Regular Inspection

Routine Checks: Regular inspections are paramount. Inspect your equipment before each use to identify any visible damage, wear, or deformation. Look for frayed wires in wire rope slings, cracks in hooks, or any irregularities in clamps and magnets.

Scheduled Detailed Inspections: Conduct detailed inspections periodically, as recommended by the manufacturer. These inspections should be more thorough and may require taking the accessory out of service for a closer look.

2. Cleaning and Storage

Cleaning: Keep your below-the-hook equipment clean by removing any debris, dust, or corrosive substances that could wear down the material. Use appropriate cleaning agents as some materials may require specific care.

Proper Storage: Store your under-hook equipment in a dry, covered area to prevent rust and corrosion. Don’t just stack them carelessly; rather, position them in specific spots where they won’t get damaged.

3. Lubrication and Corrosion Protection

Lubrication: Certain components require regular lubrication to maintain their functionality and prolong their life. Use the right type of lubricant as recommended by the manufacturer.

Corrosion Protection: Apply anti-corrosion measures, especially if the equipment are used or stored in harsh environments. Regularly check for rust and apply protective coatings when necessary.

4. Load Testing and Calibration

Regular Load Testing: Regularly test your equipment and equipment to ensure they can safely handle the maximum rated load. This is especially important for equipment that have undergone repairs.

Calibration: For equipment like lifting magnets, regular calibration is essential to ensure they operate at their intended capacity.

5. Repair and Replacement

Professional Repairs: If an accessory is damaged, have it repaired by a qualified professional. Do not attempt makeshift repairs as they can compromise safety.

Timely Replacement: Know when to replace your equipment. If an accessory fails an inspection or shows signs of significant wear, it should be replaced immediately.

6. Training and Documentation

Proper Training: Ensure that all personnel handling below-the-hook equipment are properly trained. They should understand how to inspect, maintain, and safely operate the equipment.

Maintain Records: Keep detailed records of inspections, maintenance, repairs, and replacements. This documentation is crucial for safety audits and compliance with industry regulations.

Concrete Buckets

Concrete buckets are used for transporting and pouring concrete. Essential maintenance includes regular inspections for cracks, particularly around the bail and gate mechanisms. After each use, it’s important to clean out any residual concrete to prevent hardening and obstruction.

Any signs of structural damage or malfunctioning gates necessitate immediate repair or replacement. Storing these buckets in a dry, upright position can prevent corrosion and extend their lifespan.

Self-Dumping Bins

Self-dumping bins, designed for handling waste or scrap materials, require vigilant inspection of the hinges and dumping mechanism. Ensuring the safety latch is functional is critical to prevent accidental releases. Regular cleaning to remove debris and corrosive materials will maintain structural integrity. Store these bins with the dumping mechanism locked in a corrosion-free environment to prolong their usability.

Boscaro C-N Series Hydraulic Concrete Bucket

Self-Leveling Pallet Forks

These forklift attachments, which keep loads level, need routine checks of the leveling mechanism and fork integrity. Any bending, damage, or malfunction in the leveling system should be addressed immediately to ensure safe operation. Regular lubrication of moving parts can prevent rust and ensure smooth operation. When storing, position the forks to avoid stress on the leveling mechanism.

Boscaro Auto Leveling Pallet Forks

Spreader Bars

Spreader bars are crucial for maintaining load stability during lifting operations. Inspecting the entire length for bending, cracking, or any signs of wear, especially on end fittings like hooks and shackles, is necessary. Damaged or bent spreader bars should be taken out of service immediately. Storing them in a way that prevents warping or exposure to damaging elements is essential for their maintenance.

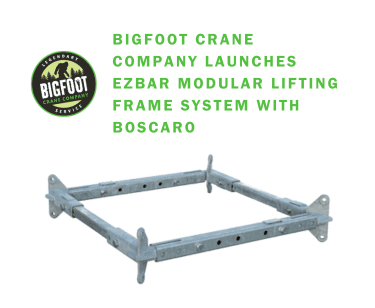

Boscaro EZ Spreader Bar System

Conclusion

Maintaining below-the-hook equipment is a continuous process that requires vigilance, knowledge, and adherence to safety standards. By implementing regular inspections, proper cleaning, and storage practices, timely repairs and replacements, and ensuring thorough training and documentation, you can significantly reduce the risk of accidents and prolong the life of your equipment. Always follow the manufacturer’s guidelines and local regulations to ensure the highest level of safety in your operations.

It’s vital to source these critical pieces of equipment from reputable suppliers. Bigfoot Crane Company Inc. offers a wide range of high-quality underhook accessories for both sale and rental. Their inventory includes a diverse selection of products designed to meet various operational needs, ensuring reliability and safety. Whether your project demands the durability of a robust concrete bucket or the precision of self-leveling pallet forks, Bigfoot Crane Company Inc. has the expertise and equipment to cater to your specific project. Their commitment to providing top-tier underhook accessories makes them a go-to source for businesses seeking to optimize their lifting and handling operations.